The Automation Imperative — Navigating Labor Shortages and CapEx Constraints with Hybrid Solutions

The Automation Imperative — Navigating Labor Shortages and CapEx Constraints with Hybrid Solutions

As labor markets tighten and CapEx budgets face increased scrutiny, many food and beverage operations are stuck between manual inefficiencies and full-scale automation investments. This paper explores how hybrid automation strategies—integrating collaborative robots, AI-driven inspection systems, and modular equipment—can bridge the gap. We’ll share real-world lessons learned from engineering firms and discuss ROI benchmarks that justify investment even in cost-constrained environments.

Executive Summary

In the face of persistent labor shortages and tighter capital budgets, food and beverage manufacturers are under immense pressure to maintain output without overextending financial resources. Full automation may seem out of reach, but the reality is more nuanced. This white paper explores how hybrid automation—smart combinations of people, equipment, and digital systems—can deliver high-impact results with manageable investment. We outline proven strategies for bridging operational gaps, mitigating workforce risks, and driving measurable ROI without a full plant overhaul.

1. The Operational Squeeze: Too Few Workers, Too Little Capital

The food and beverage sector continues to face a double threat:

- A shrinking labor pool, especially for repetitive or physically demanding tasks

- Increased scrutiny of capital projects, as cost of capital rises and ROI windows shorten

These pressures affect throughput, consistency, safety, and profitability—especially at the packaging and end-of-line stages.

2. Rethinking Automation: Beyond “All or Nothing”

Automation doesn’t have to mean replacing an entire line with robotics overnight.

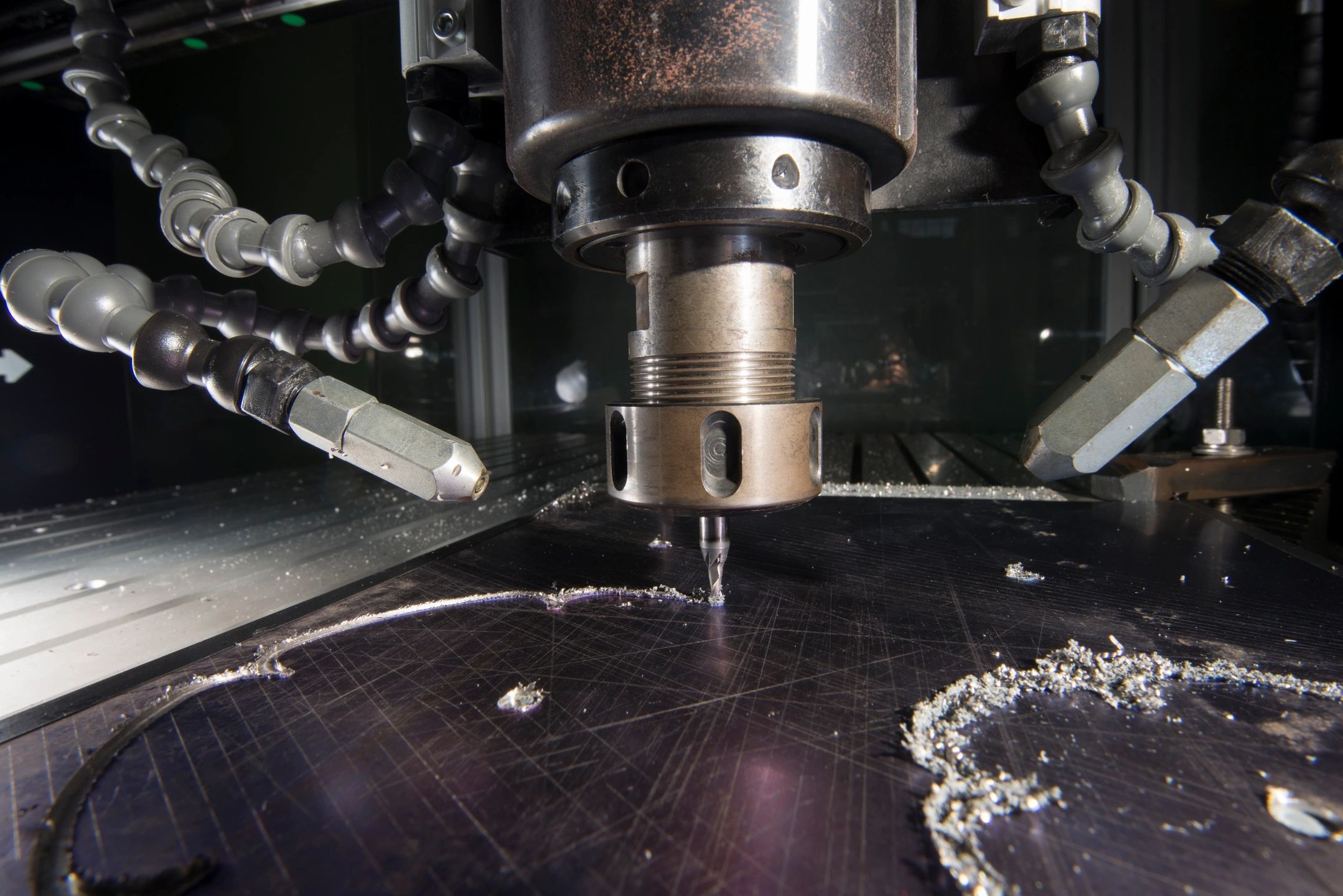

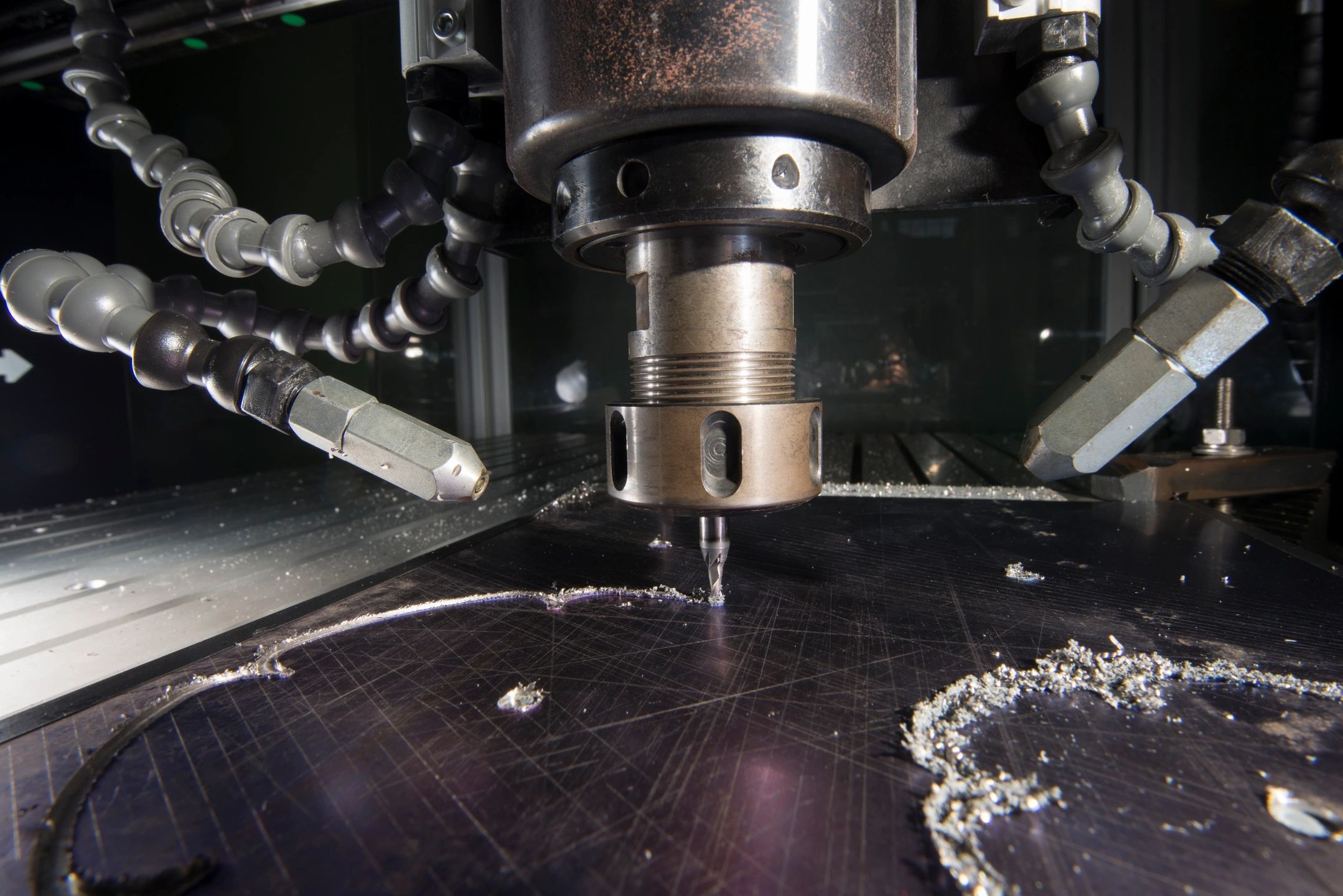

Hybrid automation is the strategic use of:

- Collaborative robots (cobots) for pick-and-place, case packing, palletizing

- Machine learning to optimize SOPs and detect line abnormalities

- Modular automation cells that integrate with existing conveyors or fillers

- Connected sensors to provide real-time data for decision-making

The payoff: Faster deployment, lower risk, and scalable ROI.

3. Where Hybrid Automation Works Best

A. Repetitive & High-Turnover Tasks

- Case packing, shrink bundling, manual labeling

- Loading/unloading pallets

Cobots and vision-guided robotics can handle these tasks 24/7—reducing fatigue, injuries, and training costs.

B. Changeovers and SKU Flexibility

- Digital SOPs and AI-based systems help operators adapt faster between SKUs.

- Recipe management software can automate machine settings during changeovers.

C. Quality & Inspection

- Automated checkweighers, X-rays, and vision systems detect errors in real-time, reducing recalls and customer complaints.

D. Performance Monitoring

- IoT systems gather data across lines and shifts—spotting inefficiencies and unlocking continuous improvement.

4. Engineering Lessons Learned: 3 Success Factors

Based on projects across the U.S. and Canada, we’ve identified key takeaways:

- Start with an Operational Audit Identify which line functions drain the most labor hours or create the most downtime.

- Design for Integration, Not Disruption Select automation tools that “bolt on” to existing lines—especially those with fast setup and minimal retraining.

- Measure What Matters Track ROI metrics such as:

- Labor hours saved

- OEE improvements

- Scrap/waste reduction

- Throughput per square foot

5. Case Snapshot: Bakery Group Replaces Manual Labor with Cobots

A regional bakery co-packer struggled with high turnover and injuries in their case- packing area.

With InnoFlex’s help, they:

- Implemented two collaborative robots within existing footprint

- Trained one operator to oversee both systems

- Integrated the cobots with their conveyor logic and ERP system

Results in 6 months:

- 48% reduction in manual labor hours

- $86K/year in labor cost savings

- Zero ergonomic injury claims since installation

6. InnoFlex's Approach: Automation with ROI, Not Risk

We specialize in:

- Line audits to identify quick automation wins

- Modular hardware + digital system integration

- Connecting automation investments to your real OpEx/CapEx goals

We don’t oversell. We co-design solutions that fit your operation, workforce, and investment capacity.

6. Conclusion: A Smarter Way to Automate

Full plant automation may be a long-term goal—but real savings and stability are possible today.

By applying targeted, flexible, and data-backed automation, F&B operations can:

- Reduce labor reliance

- Increase uptime

- Improve safety

- Stay agile under today’s economic and labor pressures